Acoustical Composites

Tecnifoam's Acoustical Foam Composites Deliver

Superior Noise Absorption and Vibration Damping

Acoustical foam composites—demanding applications

As a Twin Cities’ leading manufacturer of acoustical composites, Tecnifoam provides custom solutions for Minnesota businesses and industries.Composites are ideal in applications that demand increased noise absorption, sound transmission loss, and/or vibration damping. Our composites contain a barrier material, a high-performance acoustical foam, and a 1/4″ foam decoupler. Key composite features are:

- Easy to handle and install

- One pound per square foot loaded vinyl barrier

- Strong, durable bonds between layers are created by adhering the barrier directly to the foam

From our Circle Pines manufacturing facility, we provide custom acoustical composites to meet the unique requirements of Twin Cities manufacturers and clients.

Contact us today to get expert advice on choosing acoustic panels and sound panels

| Acoustical Composites |  |

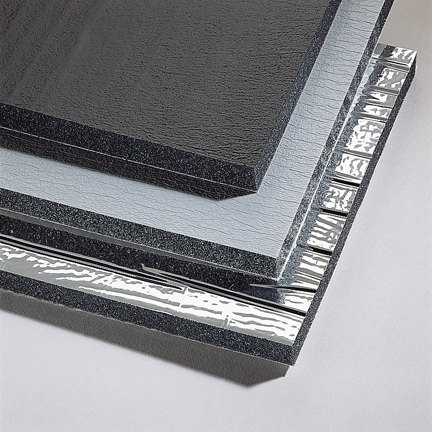

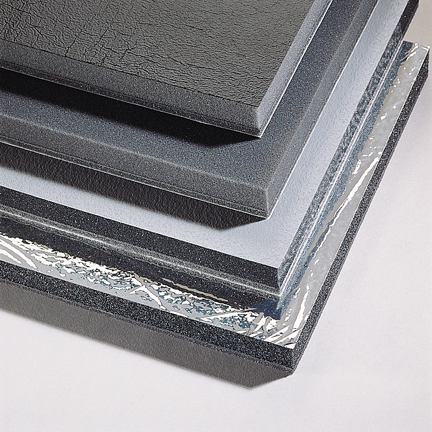

| Acoustical composites are made of open-cell polyurethane acoustical foam and available unfaced or with a variety of film facings and peel and stick backings. Pattern: flat surface with thin face Sizes: 24″ ×48″ Thickness: 1″ Density: 2 lb/cubic foot Flammability: UL94HF-1 Facings: black tuftane, gray tuftane, aluminized mylar, reinforced aluminized mylar | |

| Applications | |

|

| Frequency (Hz) | 125 | 250 | 500 | 1K | 2K | 4K | NRC |

| FTP-1 (tuftane) | .24 | .44 | .93 | .80 | .68 | .72 | .71 |

| FMP-1 (mylar) | .20 | .42 | .90 | .92 | .80 | .84 | .76 |

| Acoustical Composite Barriers |  |

| Acoustical composite barriers are made of open-cell polyurethane foam combined with 1# mass-loaded vinyl and available with a variety of film facings. Available in 1″ foam with or without facing, 1# mass-loaded vinyl, and 1/4″ foam. We can fabricate custom panels. Pattern: flat surface with or without film face Sizes: 24″ ×48″, 48″×48″ Thickness: 1.25″ Density: 2 lb/cubic foot (foam), 1 lb/cubic foot (vinyl), Flammability: UL94HF-1 Facings: black tuftane, gray tuftane, aluminized mylar, reinforced mylar unfaced: charcoal | |

| Applications | |

|

| Frequency (Hz) | 125 | 250 | 500 | 1K | 2K | 4K | NRC |

| FBF-1 (unfaced) | .04 | .38 | .77 | 1.05 | 1.09 | 1.03 | .80 |

| FBF-1T (tuftane) | .33 | .24 | .63 | 1.23 | 1.16 | 1.14 | .85 |

| Frequency (Hz) | 125 | 250 | 500 | 1K | 2K | 4K | STC |

| FBF-1 (unfaced) | 20 | 21 | 25 | 28 | 32 | 42 | 29 |

| Polyurethane Foam Barrier Composites | |

| Pattern | Flat surface or convoluted pattern |

| Sizes | 24″ ×48″, 48″×48″ |

| Thickness | 1.25″ |

| Density | 0.7 lb/cubic foot (foam), 1 lb/cubic foot (vinyl) |

| Flammability | Class 1 |

| Flame Speed | 10 |

| Smoke Density | 50 |

| Facings | Unfaced |

| Colors | Natural white, light gray, charcoal |

| Frequency (Hz) | 125 | 250 | 500 | 1K | 2K | 4K | STC |

| FBFX-1 | .04 | .51 | .78 | .89 | .92 | 1.00 | .80 |